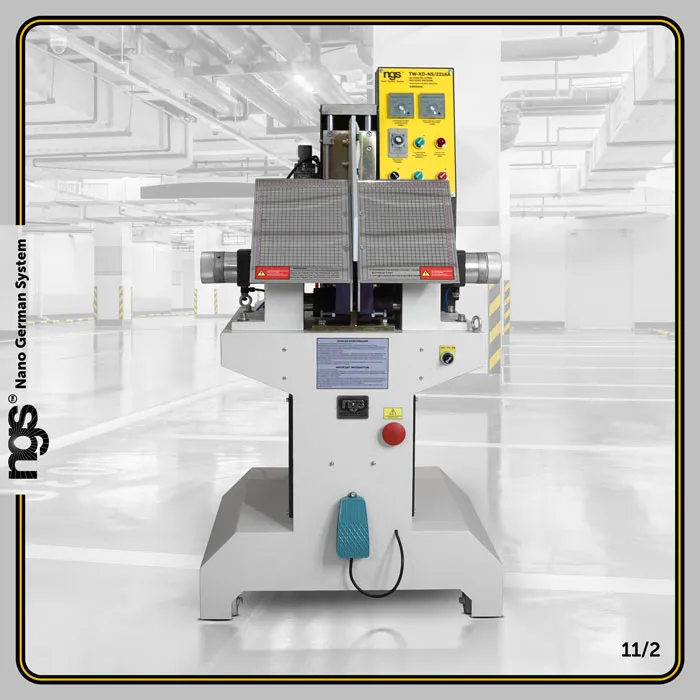

Forming shoe last pulling equipment

To optimize the process of forming the top of the shoe and adjusting the stability of the shape of the shoe one-piece high front, with one-piece vamp, as well as moccasins made from natural and eco-leather, the upper parts are preformed. If you want to optimize the manufacturing processes of footwear as much as possible - there is no way to do without equipment for forming vamps.Forming vamps is hot and cold, for each process there is a special exhaust machine for forming vamps.

First of all, hot molding is performed, usually on shoe models, where the vamp extends beyond the crest of the shoe. When forming a vamp, a certain pneumatic machine with a special knife is used, the configuration of which should exactly follow the shape of the block. For these purposes, pre-prepared templates are used. In addition to knives, in the process of forming the vamp, side clamping parts are used, which are necessary to fix the lateral parts of the vamp to the profiling blade.

The machine must necessarily have the ability to adjust the heating temperature (both the cutting element and the side fixing parts), as well as the force and time of the material.The apparatus for molding in cold mode is connected to the work after hot forming: the extraction of the vamp with a cold knife is performed a second time, immediately after hot. This sequence of actions, consisting in a sharp difference in temperature and mechanical stress, allows you to achieve a "shock state" of the upper of the shoe. Thus, the production process moves to a completely different level of quality.

This technology is required when working with PU materials.The efficiency of pneumatic machines for forming vamps is perfected to perfection: two control valves, which are located in the main and clamping cylinders, respectively exert pressure on the knife and adjust the gap between the two sides (cheeks) to give an ideal bend. Machines have the greatest possible ease of setup and ease of operation.

The international company NGS presents both hydraulic machines for cold forming of vamps and pneumatic machines both for hot forming and for both types of molding at once. This unit uses environmentally friendly refrigeration units, allowing cooling to -30 degrees Celsius. Heating is carried out using a steam system, which allows additional reactivation of the upper part, which guarantees an improved end result.

More...

Ask a Question